The compressor is the most vital part of the HVAC unit. Without a compressor, the HVAC unit couldn’t change the temperature of anything. Each type of compressor has different qualities that change its functionality. Compressors can be a little confusing at first, so here’s a brief explanation of how they work, plus some numbers to help you decide which HVAC system is the best fit for your home.

How do HVAC compressors work?

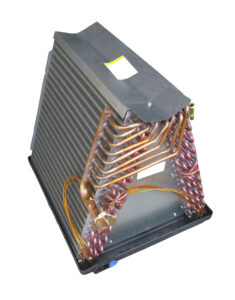

Each type of compressor works a little differently, but the idea is generally the same. Each HVAC system contains an evaporator coil placed below a compressor. This evaporator coil (see the image below) contains refrigerant, which it evaporates over time. The vaporized refrigerant is guided into the compressor, which increases its pressure in order to increase the temperature of the vapor refrigerant. (For any nerds out there like me, this is due to the Ideal Gas Law: PV = nRT.)

The warmed vapor refrigerant then travels from the higher pressure of the compressor back to the lower pressure of the evaporator coil. Once the vapor refrigerant exits the compressor, it is in a lower pressure state and so condenses, cools, and becomes a liquid once again. The heat expelled from the refrigerant during this decompression process is transferred to outside the home, and the process repeats.

What are the different types of HVAC compressors, and what are the benefits of each?

| Reciprocating | Rotary-vane | Rotary-scroll | Rotary-screw | Centrifugal | |

| Cost per kW | Low | Medium | Medium | High | High |

| Efficiency | Low | Medium | High | Very high | Very high |

| Vibrations | High | Moderate | Moderate | Lowest | Lowest |

| Manufacturing accuracy | Easy | Difficult | Difficult | Very difficult | Very difficult |

| Input power per unit | Low-high | Low | Low | High | High |

| Other | Run on oil and gas, low cost of installation. | Constant performance, minimal wear. Oil. | Small, quiet, no metal or lubrication. Oil-free. | High reliability, quiet. Oil. | No valves, pistons, cylinders. Oil-free. |

Which compressor is the most environmentally efficient?

Based on the data above, the rotary-screw and centrifugal compressors are the most efficient; they are able to produce the most cool air. However, they each also require the most “input power per unit,” or the most power to run their compression processes.

The rotary-scroll compressor requires a low input power and has a high efficiency. This difference in power input to power output is the largest of any of the compressors. Additionally, it has the option of being oil-free, thus making it one of the cleanest options. The rotary-scroll compressor is therefore the most environmentally efficient.

Which HVAC compressor is the most cost-efficient?

The table above shows that the least expensive option is the reciprocating HVAC compressor; however, this compressor also has a low efficiency and high amounts of vibration and so isn’t the best choice overall. The type of compressor with the lowest cost, highest efficiency, and lowest power input is also the rotary-scroll.

Which HVAC compressor would therefore be best for my home?

Based on the table above, the rotary-scroll is the best option; it has an average cost, high efficiency, and requires a low power input, thus making it the most efficient compressor both in terms of the environment and cost.

However, this answer will depend on how much money you’re willing to spend on your compressor. Generally, more expensive means that the compressor lasts longer, has a higher efficiency, or has a longer warranty, so it’s usually worth it to get more expensive.

The compressor isn’t the only part of your HVAC system that matters, so be sure to research how the other components affect the efficiency, cost, and input power of your unit. But as you choose an HVAC system, be sure to take into account the compressor it utilizes.

References

https://www.apc.com/salestools/VAVR-AE7T7G/VAVR-AE7T7G_R0_EN.pdf